Centrifugal vs. AODD: Which Pump Do You Actually Need?

Choosing the right pump can be the difference between a smooth operation and a maintenance nightmare. Here is a quick breakdown of the two industry heavyweights: Centrifugal Pumps and Air-Operated Double-Diaphragm (AODD) Pumps.

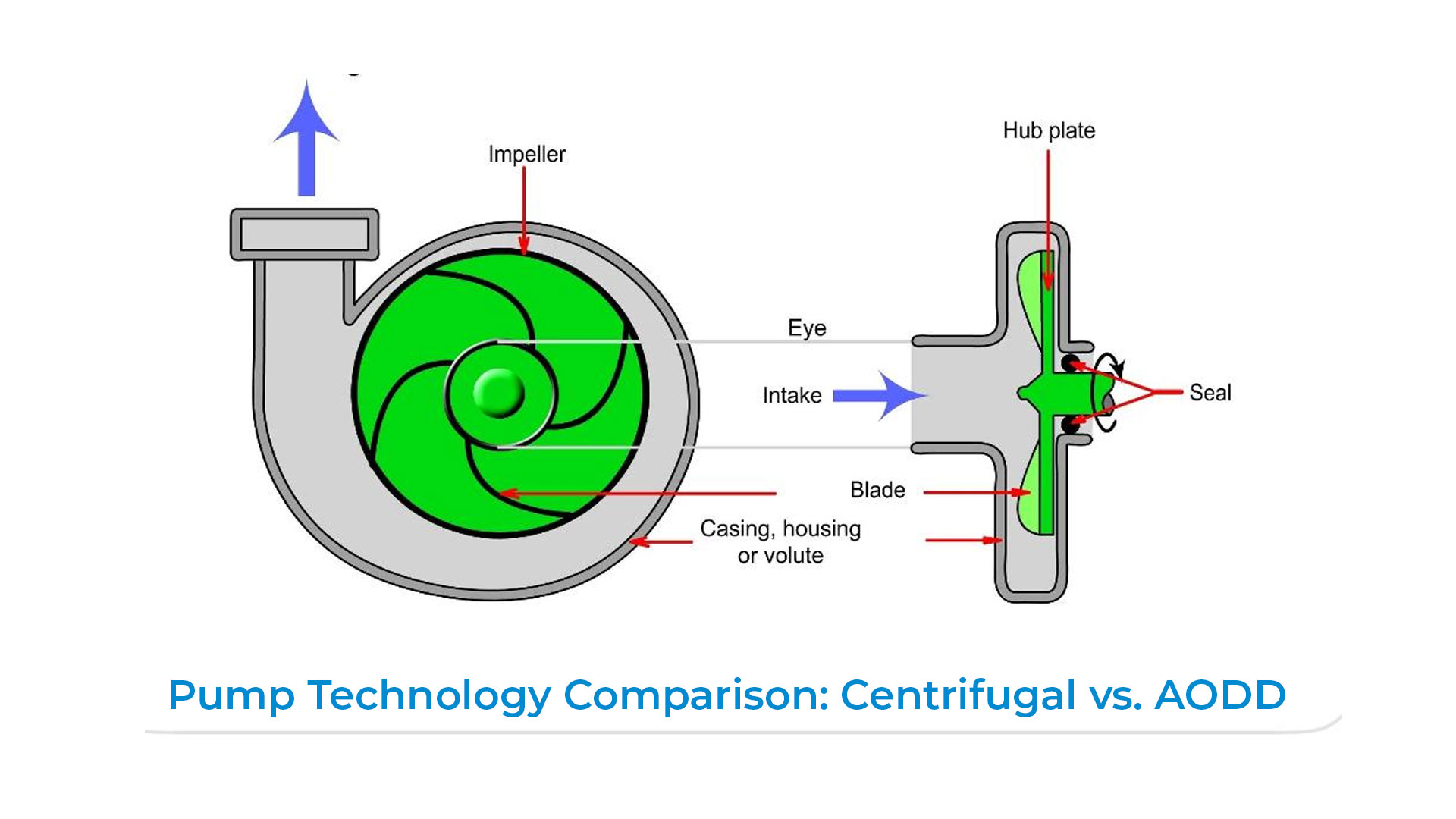

Centrifugal Pumps: The High-Speed Workhorse

Centrifugal pumps use kinetic energy (a spinning impeller) to "fling" fluid outward. They are designed for speed and volume.

* Best for: Water, thin chemicals, and high-flow applications.

* Pros: Steady, non-pulsing flow; high efficiency; lower operating costs.

* Cons: Cannot run dry (seals will fail); usually requires priming; struggles with thick fluids or large solids.

AODD Pumps: The Rugged Problem Solver

AODD pumps are positive displacement pumps driven by compressed air. They use reciprocating diaphragms to "push" fluid through.

* Best for: Sludge, slurries, shears-sensitive liquids (like food), and hazardous environments.

* Pros: Self-priming; can run dry indefinitely without damage; handles large solids; explosion-proof by nature (no electricity).

* Cons: Pulsating flow (requires dampeners for a steady stream); less energy-efficient (uses compressed air); noisier operation.

#aodd

#aoddpumps

#aoddpumpsindia

#centrifugal

#Centrifugalpump

#TheHighSpeedWorkhorse

#TheRuggedProblemSolver

#maxworthmarketing